Integrating Microelectronics Contexts into Engineering Classrooms: Thermo-Calc Online Tool for the Design of Solder Materials

Integrating Microelectronics Contexts into Engineering Classrooms: Thermo-Calc Online Tool for the Design of Solder Materials

-

1. Integrating Microelectronics C…

0

00:00/00:00

1. Integrating Microelectronics C…

0

00:00/00:00 -

2. Integrating Microelectronics C…

83.917250583917252

00:00/00:00

2. Integrating Microelectronics C…

83.917250583917252

00:00/00:00 -

3. Outline

103.50350350350351

00:00/00:00

3. Outline

103.50350350350351

00:00/00:00 -

4. What are soldering materials?

128.59526192859528

00:00/00:00

4. What are soldering materials?

128.59526192859528

00:00/00:00 -

5. Soldering in microelectronics

208.14147480814148

00:00/00:00

5. Soldering in microelectronics

208.14147480814148

00:00/00:00 -

6. Solder design & Phase diagrams

356.38972305638976

00:00/00:00

6. Solder design & Phase diagrams

356.38972305638976

00:00/00:00 -

7. Contextualization in materials…

479.91324657991328

00:00/00:00

7. Contextualization in materials…

479.91324657991328

00:00/00:00 -

8. Situated learning and student …

510.276943610277

00:00/00:00

8. Situated learning and student …

510.276943610277

00:00/00:00 -

9. Contextualization in materials…

672.00533867200534

00:00/00:00

9. Contextualization in materials…

672.00533867200534

00:00/00:00 -

10. Outline

735.13513513513522

00:00/00:00

10. Outline

735.13513513513522

00:00/00:00 -

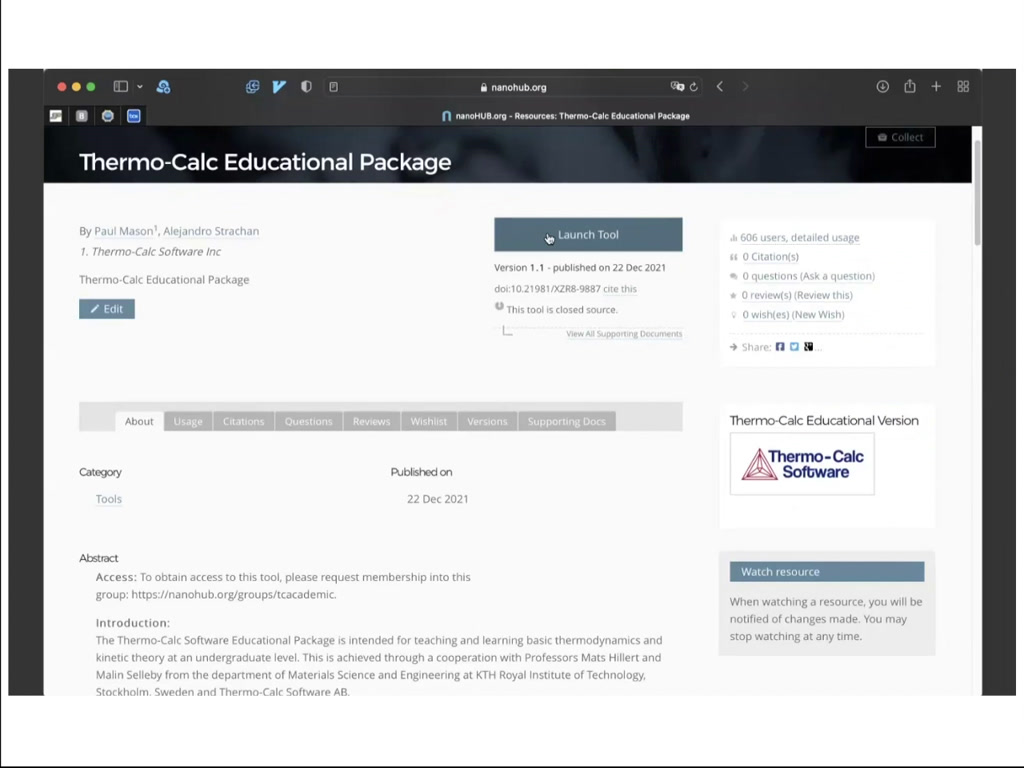

11. Thermo-Calc Educational Packag…

743.47681014347688

00:00/00:00

11. Thermo-Calc Educational Packag…

743.47681014347688

00:00/00:00 -

12. Hands-on Demo

745.47881214547886

00:00/00:00

12. Hands-on Demo

745.47881214547886

00:00/00:00 -

13. (1) Binary Phase Diagrams: Low…

765.16516516516515

00:00/00:00

13. (1) Binary Phase Diagrams: Low…

765.16516516516515

00:00/00:00 -

14. (1) Binary Phase Diagrams: Low…

868.23490156823493

00:00/00:00

14. (1) Binary Phase Diagrams: Low…

868.23490156823493

00:00/00:00 -

15. (1) Binary Phase Diagrams: Low…

884.617951284618

00:00/00:00

15. (1) Binary Phase Diagrams: Low…

884.617951284618

00:00/00:00 -

16. Hands-on Demo

928.6953620286954

00:00/00:00

16. Hands-on Demo

928.6953620286954

00:00/00:00 -

17. Hands-on Demo

1026.65999332666

00:00/00:00

17. Hands-on Demo

1026.65999332666

00:00/00:00 -

18. Hands-on Demo

1201.801801801802

00:00/00:00

18. Hands-on Demo

1201.801801801802

00:00/00:00 -

19. (1) Binary Phase Diagrams: Low…

1252.218885552219

00:00/00:00

19. (1) Binary Phase Diagrams: Low…

1252.218885552219

00:00/00:00 -

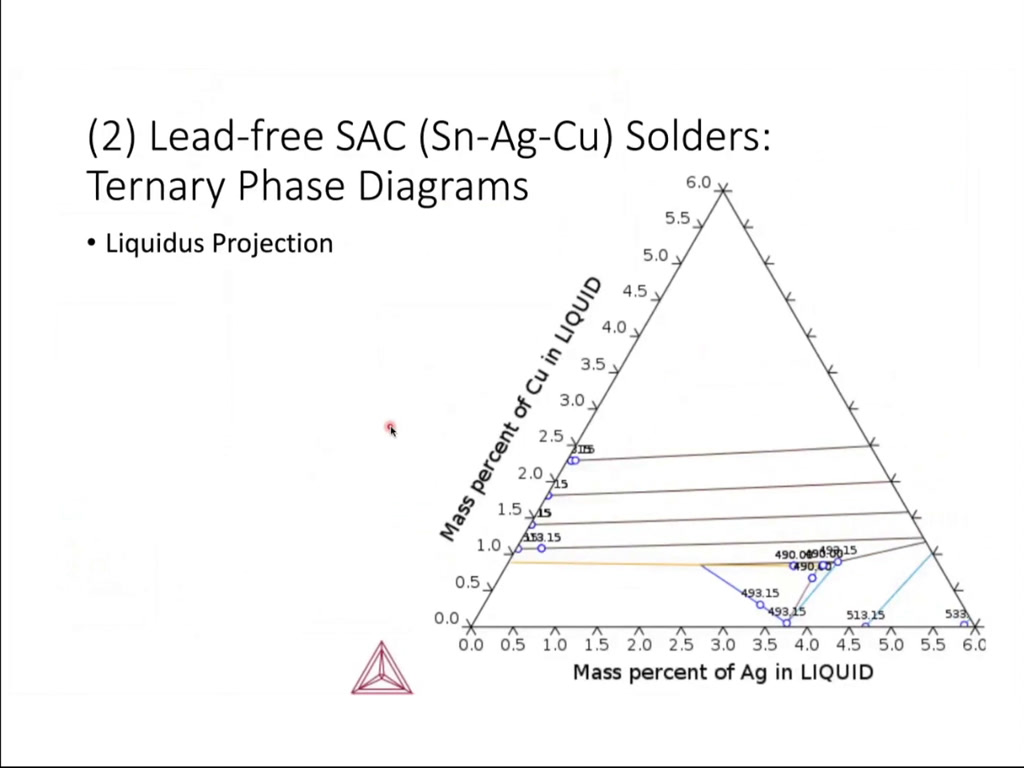

20. (2) Lead-free SAC Solders: Ter…

1352.318985652319

00:00/00:00

20. (2) Lead-free SAC Solders: Ter…

1352.318985652319

00:00/00:00 -

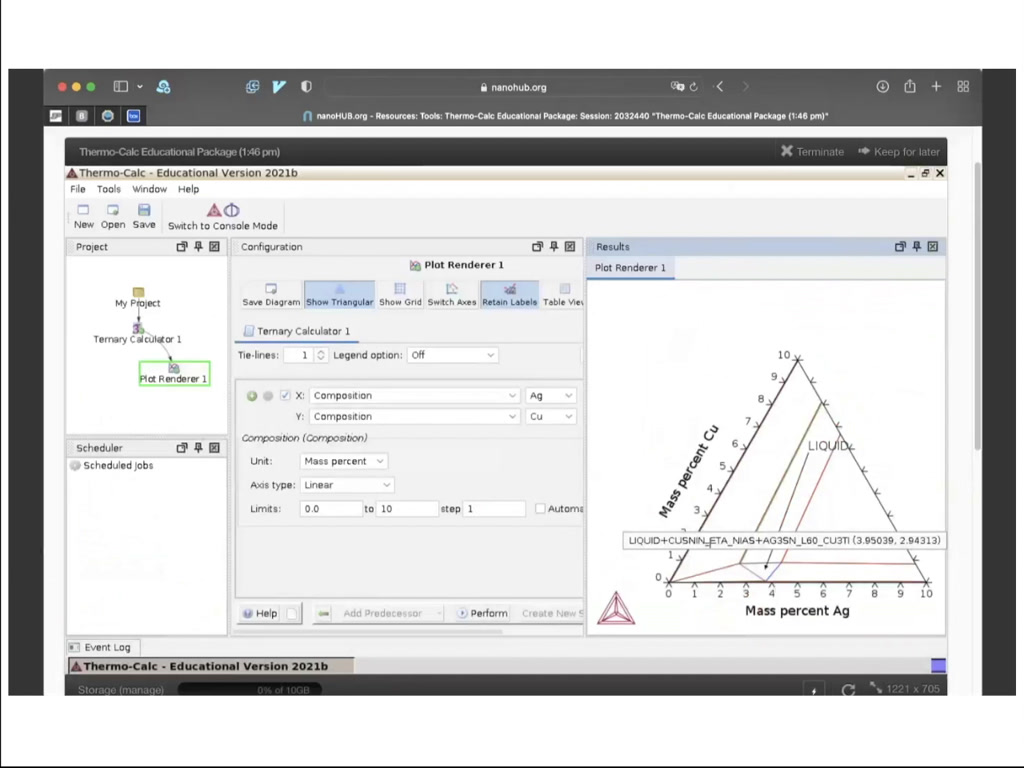

21. Hands-on Demo

1384.2842842842842

00:00/00:00

21. Hands-on Demo

1384.2842842842842

00:00/00:00 -

22. Hands-on Demo

1396.3630296963631

00:00/00:00

22. Hands-on Demo

1396.3630296963631

00:00/00:00 -

23. Hands-on Demo

1616.816816816817

00:00/00:00

23. Hands-on Demo

1616.816816816817

00:00/00:00 -

24. (2) Lead-free SAC Solders: Ter…

1653.1531531531532

00:00/00:00

24. (2) Lead-free SAC Solders: Ter…

1653.1531531531532

00:00/00:00 -

25. Hands-on Demo

1658.6586586586586

00:00/00:00

25. Hands-on Demo

1658.6586586586586

00:00/00:00 -

26. (2) Lead-free SAC Solders: Ter…

1835.301968635302

00:00/00:00

26. (2) Lead-free SAC Solders: Ter…

1835.301968635302

00:00/00:00 -

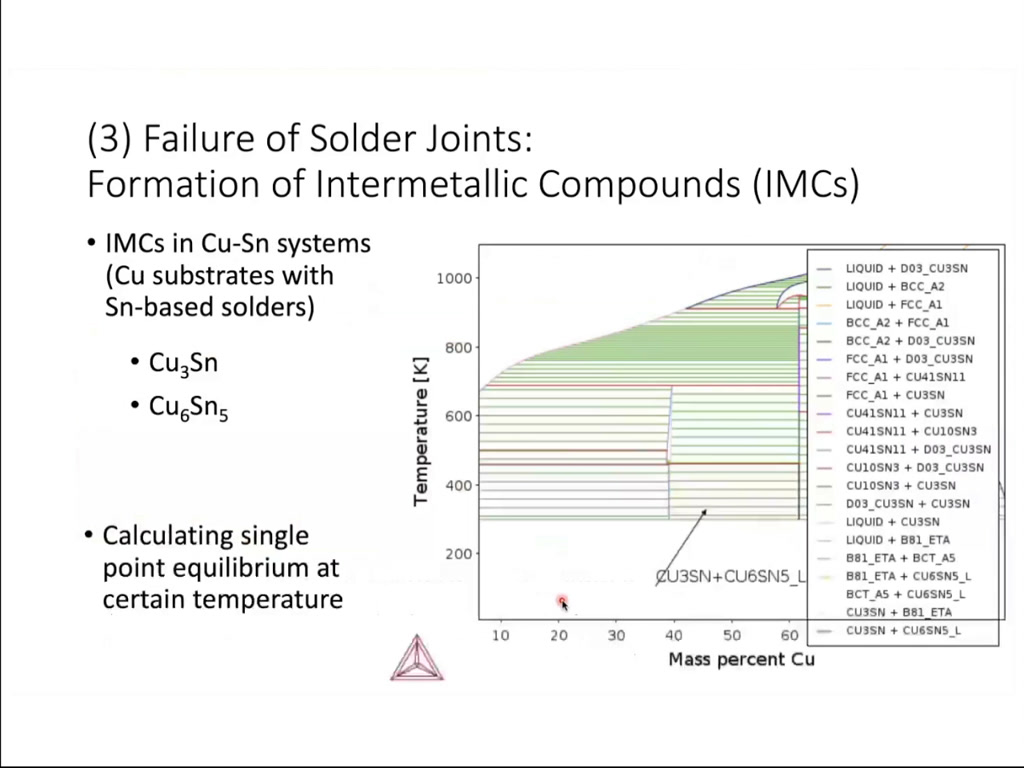

27. (3) Failure of Solder Joints: …

1839.3393393393394

00:00/00:00

27. (3) Failure of Solder Joints: …

1839.3393393393394

00:00/00:00 -

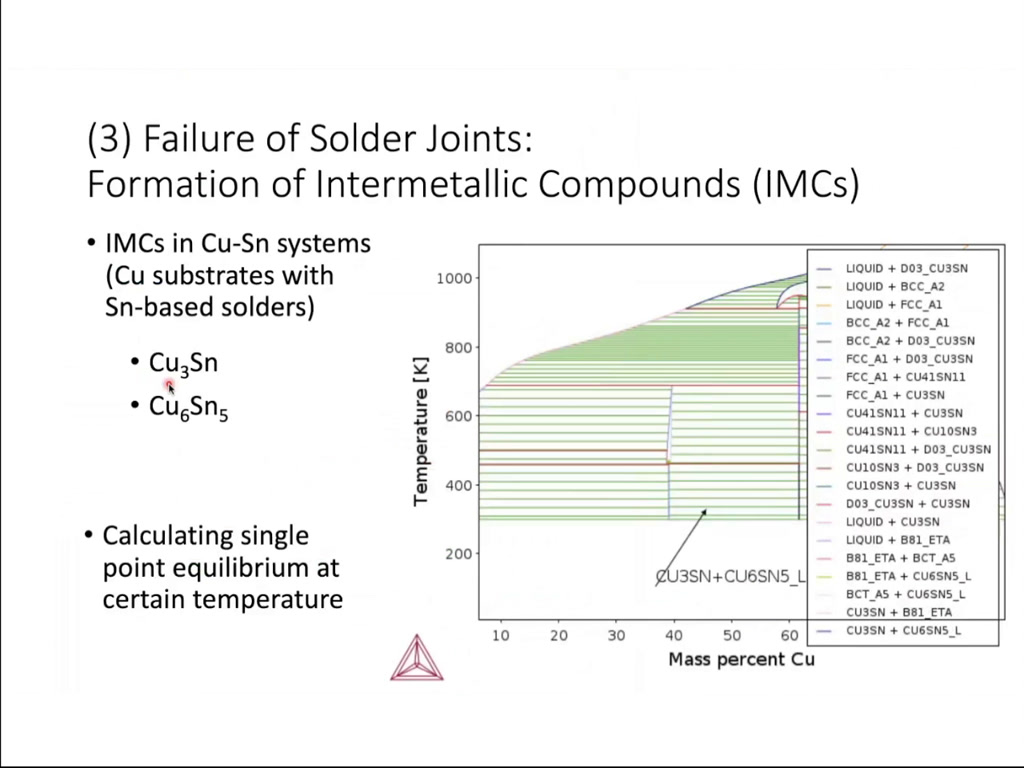

28. (3) Failure of Solder Joints: …

1926.2595929262598

00:00/00:00

28. (3) Failure of Solder Joints: …

1926.2595929262598

00:00/00:00 -

29. Hands-on Demo

1955.8558558558559

00:00/00:00

29. Hands-on Demo

1955.8558558558559

00:00/00:00 -

30. Hands-on Demo

1964.4978311644979

00:00/00:00

30. Hands-on Demo

1964.4978311644979

00:00/00:00 -

31. (3) Failure of Solder Joints: …

2103.5702369035703

00:00/00:00

31. (3) Failure of Solder Joints: …

2103.5702369035703

00:00/00:00 -

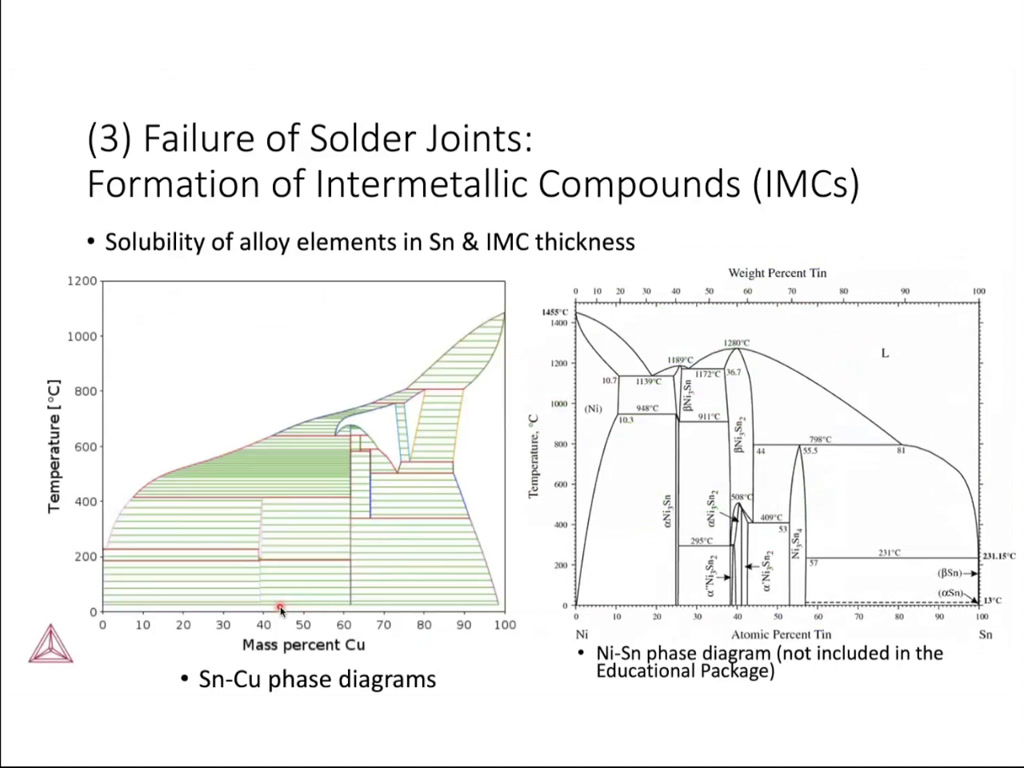

32. (3) Failure of Solder Joints: …

2150.0166833500166

00:00/00:00

32. (3) Failure of Solder Joints: …

2150.0166833500166

00:00/00:00 -

33. (3) Failure of Solder Joints: …

2230.0633967300637

00:00/00:00

33. (3) Failure of Solder Joints: …

2230.0633967300637

00:00/00:00 -

34. (3) Failure of Solder Joints: …

2268.1348014681348

00:00/00:00

34. (3) Failure of Solder Joints: …

2268.1348014681348

00:00/00:00 -

35. Hands-on Demo

2306.9736403069737

00:00/00:00

35. Hands-on Demo

2306.9736403069737

00:00/00:00 -

36. (3) Failure of Solder Joints: …

2384.8515181848516

00:00/00:00

36. (3) Failure of Solder Joints: …

2384.8515181848516

00:00/00:00 -

37. (4) Reflow Solidification Proc…

2417.1504838171504

00:00/00:00

37. (4) Reflow Solidification Proc…

2417.1504838171504

00:00/00:00 -

38. Hands-on Demo

2458.0580580580581

00:00/00:00

38. Hands-on Demo

2458.0580580580581

00:00/00:00 -

39. (4) Reflow Solidification Proc…

2596.83016349683

00:00/00:00

39. (4) Reflow Solidification Proc…

2596.83016349683

00:00/00:00 -

40. Summary

2606.6066066066069

00:00/00:00

40. Summary

2606.6066066066069

00:00/00:00 -

41. Thank You

2661.3279946613279

00:00/00:00

41. Thank You

2661.3279946613279

00:00/00:00