NCN Undergraduate Research Projects 2017

This page presents the research areas that NCN SURF students may participate in during Summer 2017. Be sure to follow the directions on the SURF application page and select "Network for Computational Nanotechnology (NCN) / nanoHUB" as one of your top choices. More information about the NCN-SURF program is on our main page. Indicate your specific project preference and qualifications in your SURF application.

Predictive modeling and simulations of materials: from atoms to devices

Faculty Advisor: Alejandro Strachan

Project Description: Our research focuses on the development of predictive atomistic and molecular simulation methodologies to describe materials from first principles, their application to problems of technological importance and quantification of associated uncertainties. Several SURF projects will be available this summer including the following areas:

- Molecular simulations of resistance switching devices of interest for memory and logic applications in nanoelectronics

- Design of metamaterials with thermo-mechanical properties not achievable otherwise like ultra-low stiffness

- Simulations of carbon fibers that offer unique combination of specific strength and stiffness

- Simulations of chemical reactions under extreme conditions of pressure and temperature

Suggested Majors: Physics, Materials Science and Engineering, Chemistry, Computer Science.

Required Skills: College-level math and physics, some experience with simulations.

Additional Desired Skills, Courses Completed: Quantum atomic and molecular physics, programming experience.

Dynamic fracture of composite materials

Faculty Advisor: Marisol Koslowski

Project Description: Fracture in composite materials is influenced by the microstructure, and interfacial bonding strength between the particles and the binder. Therefore, incorporating details of the microstructure is of critical importance to develop predictive models of failure under dynamical loading. In this project finite elements simulations of damage will be used to investigate crack initiation and propagation in polymer composites and the macro and mesoscale. A systematic study of the particle stiffness, the surface energy of the matrix-particle interfaces and the particle distribution will elucidate the influence of these properties on the crack path and the failure mechanisms observed experimentally.

Suggested Majors: Mechanical Engineering, Materials Engineering.

Desired Skills: Mechanics of Materials, Linux.

Project 1: Modeling and Optimizing Experimentally Fabricated and Characterized Thermophotovoltaic Devices

Faculty Advisor: Peter Bermel

Project Description: Waste heat is an abundant resource, recoverable from the environment via the emerging technology of thermophotovoltaics (TPV). In TPV, a hot emitter illuminates a low-bandgap solar cell to generate electricity. Making this technology relevant to current energy challenges requires designing new types of experimentally-relevant thermal emitters and photovoltaic diodes for high performance. In our nanoHUB SURF research, we will incorporate experimental measurements into our GUI-based simulation tool to capture the optical, thermal, and electrical performance of a TPV system. We will use this to prioritize future experimental efforts in the field, and make these capabilities globally available. Our tool will be hosted and run through nanoHUB.org - an open-access science gateway for cloud-based simulation tools and resources in nanoscale science and technology.

Suggested Majors: Electrical Engineering, Physics, Materials Science, Computer Engineering.

Required Skills: Basic knowledge of freshman or sophomore-level introductory electromagnetism, as well as basic programming knowledge.

Additional Desired Skills: Prior exposure to scientific modeling is desirable. Knowledge of semiconductor devices, and how to model them using the drift-diffusion and heat diffusion equations for current and heat transport is not required, but a significant plus. Motivation and ability to quickly learn new topics as needed is highly desirable. For coding, Python and MATLAB/Octave are our preferred languages.

Project 2: Modeling High-Efficiency Rear-Junction Photovoltaic Devices

Faculty Advisor: Peter Bermel

Project Description: Photovoltaic module design has been rethought to increase efficiency and thus take greater advantage of the abundant solar energy available to us. Traditionally, photogenerated charge carriers in a solar cell are collected at the front of the cell. However, materials advancements now allow for collection at the rear of the cell, which is observed to enhance device efficiency. We have made advancements in explaining the physical mechanisms behind observed high efficiency with a physics-based model. However, continued work is necessary to realize the full physical mechanisms behind the world-record success of rear-contact photovoltaics. Modeling advancements from this project will lead to development of a tool to accurately model rear-contact photovoltaic devices. Our tool will be hosted and run through nanoHUB.org - an open-access science gateway for cloud-based simulation tools and resources in nanoscale science and technology.

Suggested Majors: Electrical Engineering, Physics, Materials Science, Computer Engineering

Required Skills: Basic knowledge of semiconductor device fundamentals, knowledge of introductory electromagnetism, basic programming knowledge.

Additional Desired Skills: Knowledge of photovoltaic devices is helpful but not required. Experience with scientific modeling. Motivation and ability to quickly learn new topics as needed is highly desirable.

Developing a predictive model for nanocluster evolution under irradiation

Faculty Advisor: Janelle Wharry

Project Description: Irradiation causes Ni-Si-Mn-Cu nanoclusters to nucleate in ferritic stainless steels. In other steels that contain pre-existing oxide nanoclusters, irradiation causes changes to the size and composition of these nanoclusters. If such steels are used for structural components within a nuclear power plant, the irradiation-induced nanocluster evolution will have long-term consequences on the mechanical properties, performance, and operational safety margins of the structure. Thus, it is of utmost importance to understand how irradiation affects nanoclusters, in order to mitigate the impact on long-term material performance. Our research group has developed a model to predict the evolution of various types of nanoclusters under various types of irradiation. We are now looking for a student to code this model into a more user-friendly environment. This project will involve: (1) becoming familiar with the model, which is based on a series of differential equations, (2) coding the model in your programming language of choice and checking it against existing results, and (3) developing a user interface and writing a user guide/manual.

Suggested Majors: Materials Engineering, Computer Science, Nuclear Engineering.

Required Skills: Knowledge of a programming language such as Matlab, C/C++, or Fortran. Basic knowledge of metals, their crystal structures, and point defects. Familiarity with differential equations.

Additional Desired Skills: Curiosity in the subject matter, ability to work both collaboratively and independently.

Project 1: Modeling of phase transforming cellular materials (PXCMs)

Faculty Advisor: Pablo D. Zavattieri

Project Description: Active materials like shape memory, ferroelectric and magnetostrictive alloys obtain their characteristic properties due to phase transformations. In these materials, phase transformations occur by changing the packing arrangement of the atoms in a process that resembles multistable mechanisms switching between stable configurations. A similar behavior has been observed in folded proteins in which a change in configuration (e.g. from folded to unfolded) provides the mechanism through which biological materials obtain remarkable properties such as combinations of strength and toughness, superelasticity and shock energy dissipation, among others (See Figure 1(a)-(b)). Phase transformations can be extended to cellular materials by introducing materials whose unit cells have multiple stable configurations. Each stable configuration of the unit cell corresponds to a phase, and transitions between these phases are interpreted as phase transformations for the material (See Figure 1(c)). It has been demonstrated that phase transforming cellular materials (PXCMs) offer innovative advantages for energy dissipation without relying in the inelastic behavior of its base material making PXCMs attractive for many applications like: automobiles, protective gear, or buildings [1]. In this project we propose to develop a simulation tool that predicts the mechanical behavior of PXCMs given the response of its unit cell. It is expected that the successful implementation of this simulation tool can be used to create design guidelines for new PXCM designs with improved energy absorption.

Suggested Majors: Civil engineering, Mechanical engineering, Aerospace engineering.

Required Skills: Basic physics, Basic mechanics and Solid mechanics.

Additional Desired Skills: Numerical methods, introduction to programming and basic knowledge in CAD software.

Project 2: Coarse-grained model for mechanical behavior of CNC composite

Faculty Advisor: Pablo D. Zavattieri

Project Description: In the past decade, many researchers have studied mechanical properties of polymer reinforced nanocomposites, theoretically and experimentally, to understand and improve the performance of materials [1]. Understanding the role of matrix, fiber and the interface between fiber and matrix in mechanical properties is crucial for developing a material with desired and consistent mechanical properties. Recently, crystalline Nano cellulose (CNC) has gained considerable attention as natural, strong fiber for nanocomposite applications [1-4]. Cellulose is a linear chain of 1-4 linked β-D glucopyranose and can be extracted from plants (e.g., wood, cotton), algae, bacteria, and some marine creatures (e.g., tunicates). Naturally synthesized cellulose (cellulose I) has crystal-like regains with two distinct polymorphs called cellulose Iα and Iβ [1]. Cellulose Iβ is the more stable phase, dominant in plants and the focus of this project. There are many aspects of CNCs that can affect the overall mechanical properties of the nanocomposite such as fiber content, aspect ratio or length of the CNC and degree of alignment. Here we develop a modeling tool to study the effect of microstructure, changed by fiber contend, alignment or length of CNC, on the mechanical properties and failure mechanism. To be able to model the chemical structure of CNC-nanocomposite, in particular all atoms and molecules, molecular dynamics (MD) seems to be the best option. However, MD simulations become very expensive for big structures (more than 1,000,000 atoms). In addition, modeling all atoms for capturing only the mechanical properties is not necessary. As a second approach, we developed a coarse-grained model for CNC-nanocomposite which reduces the number of atoms and bridge the length and time scale dramatically. We have already developed a coarse-grained model for CNC, Fig. 1, and a nanoHUB tool for mechanical properties of CNC bio-inspired structure [4] as shown in Fig. 2. The new development would be a coarse-grained model for the matrix and generating appropriate microstructure based on fiber content and alignment of the composite as shown in Fig. 2. Finally the mechanical tests are applied to the generated structure and stress-strain and energy curves will be obtained and plotted in the nanoHUB tool.

Figure 1. Structure of CNC and development of coarse-grained model for mechanical properties [6].

2a) 2b)

Figure 2. (a) comparing the mechanical properties of PLA obtained from the coarse-grained and MD simulations. (b) Interaction of CNC-PLA for modeling interface properties.

Suggested major(s): Civil engineering, Mechanical engineering, Aerospace engineering

Required skills, courses completed: Basic physics, Python and/or C programming.

Additional desired skills, courses completed: Numerical methods, Molecular dynamics (MD).

References

[1] R.J. Moon, A. Martini, J. Nairn, J. Simonsen, J. Youngblood, “Cellulose nanomaterials review: Structure, properties and nanocomposites”, Chemical Society Reviews, 40, pp. 3941–3994, 2011

[2] Y. Cao, N. Tian, D. Bahr, P.D. Zavattieri, J. Youngblood, R.J. Moon, J.Weiss, “The influence of cellulose nanocrystals on the microstructure of cement paste”, Cement and Concrete Composites, 74, pp. 164-173, 2016.

[3] Y. Cao, P. Zavattieri, J. Youngblood, R. Moon, J. Weiss, “The relationship between cellulose nanocrystal dispersion and strength”, Construction and Building Materials, 119, pp. 71–79, 201

[4] Lee SY, Mohan DJ, Kang IA, Doh GH, Lee S, Han SO. “Nanocellulose reinforced PVA composite films: effects of acid treatment and filler loading”. Fiber Polym 10(1):77–8, 200

[5] H.P.S. Abdul Khalil, A.H. Bhat, A.F. Ireana Yusra Green composites from sustainable cellulose nanofibrils: a review Carbohydr Polym, 87 pp. 963–979, 201

[6] K. Tian, M. Shishehbor, and P. D. Zavattieri, “Bio-inspired Crystalline Nano-Cellulose coarse graining toolkit,” https://nanohub.org/resources/cgmcc, 2016.

Computational modeling of heterogeneous catalysis on nanostructures

Faculty Advisor: Peilin Liao

Project Description: We are interested in developing oxide catalysts for oxygen reduction reaction (ORR) and oxygen evolution reaction (OER). Slow kinetics in these reactions limit the efficiencies of fuel cells, solar cells, and metal-air batteries.

First-principles computational methods have been shown to be valuable tools to gain insights into atomistic and electronic structures of catalytic surfaces and reactive intermediates. Scaling relationships have been proposed to relate binding energies to reaction barriers and reaction rates.

In this project, the student will learn basic theory and develop Python interface to set up structural models, running calculations, and analyzing computational results.

Suggested Majors: Materials Science, Chemical Engineering, Chemistry, Physics, Electrical Engineering, Mechanical Engineering, Computer Science.

Required Skills: College-level general chemistry and physics. Programming course.

Additional Desired Skills: Python.

Project 1: Statistical correlations and modeling methods for multi-physics/scale manufacturing processes

Faculty Advisor: Ilias Bilionis

Project Description: Advanced manufacturing processes are characterized by complicated physical relationships that are sometimes difficult to model based on their physical and chemical basis. Alternatively, statistical response methodologies use experimental data to learn the map between process inputs and outputs without the need for precise physical knowledge. Due to the use of design of experiment (DoE) method that minimizes the number of experiments, the variations in the input parameters deviate from the linear behavior in order to cover larger space of the operation conditions. Thus, generation of response surfaces will aid in drawing observations in the trend of the output results to the input conditions. The student working on this project will be expected to familiarize her(him)self with state-of-the-art statistical methods to generate response surfaces for experimental results. These results come from large scale production of graphene using plasma roll-to-roll chemical vapor deposition. Hence, the student will have the chance to explore this field in nanotechnology by modeling the quality of the graphene with the input parameters.

Suggested Majors: Computer Science, Statistics, Mathematics, Engineering.

Required Skills:

- Programming, preferably Python

- Calculus, Linear Algebra

- Computer Programming

- Basic Probability and Statistics

Additional Desired Skills:

- Numerical methods

- Bayesian probability

- Optimization

- Parallel computing

- Differential equations.

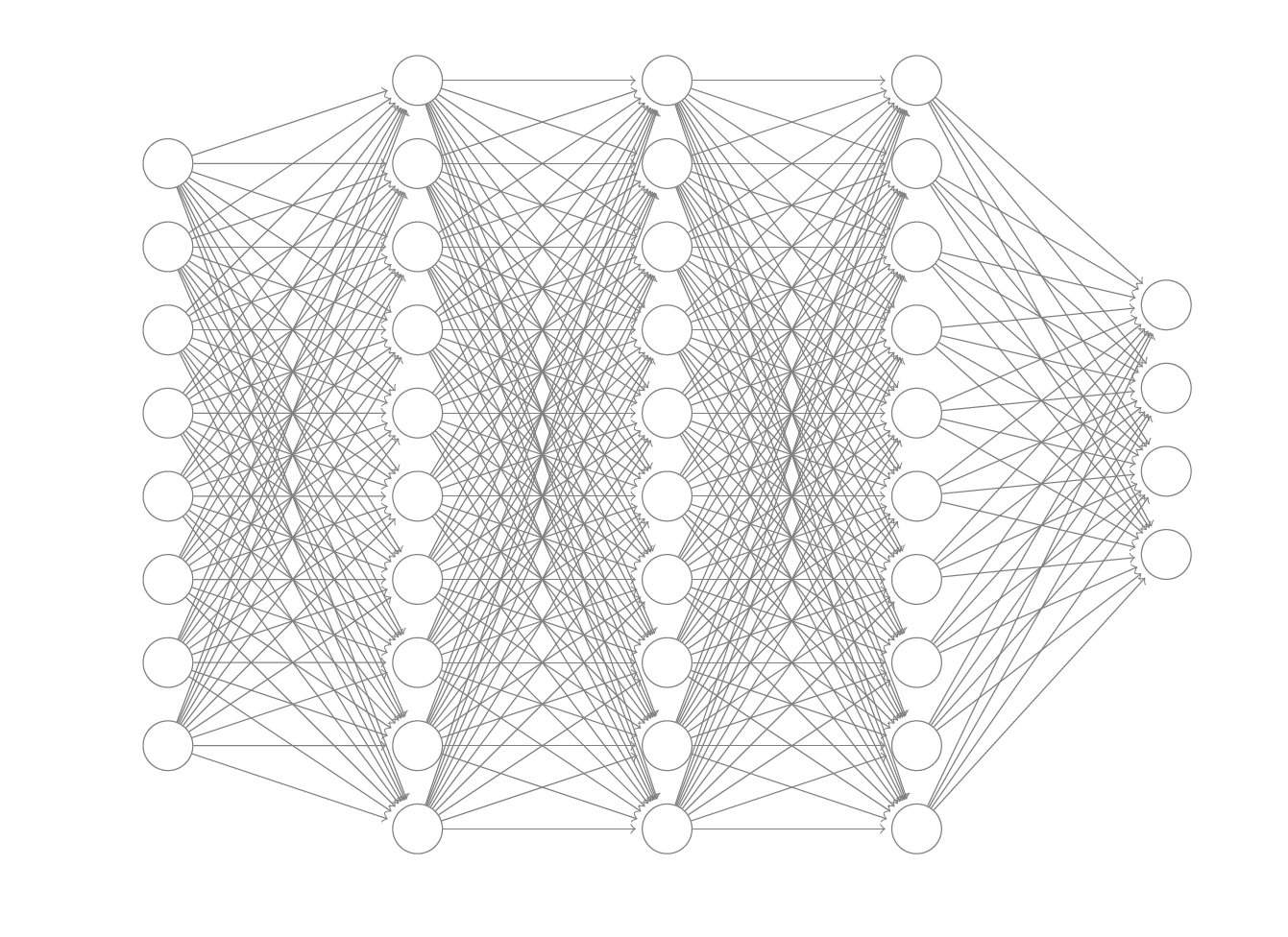

Project 2: Deep neural networks for solving stochastic elliptic partial differential equations (PDEs)

Faculty Advisor: Ilias Bilionis

Project Description: Elliptic partial differential equations characterize numerous phenomena in engineering and physics – such as the mechanics of composite materials and flow through porous media. The solution of these partial differential equations is often complicated by the uncertainties in their coefficients or boundary conditions and one must resort to formulating the problem in a stochastic framework. We take up a data driven approach using deep neural networks to characterize the statistics of the solution of a stochastic elliptic PDE using deep neural networks; which have found tremendous success, in recent years, in complex data driven tasks in the field of computer vision and AI.

The student working on this project will be expected to familiarize her(him)self with state-of-the-art deep learning modules (such as tensorflow) and experiment with network architecture and hyperparameters to build a surrogate that maps the coefficient of a stochastic PDE and its solution.

Suggested Majors: Computer Science, Statistics, Mathematics, Engineering.

Required Skills: Programming (preferably python), Calculus, Linear algebra, Computer programming, basic probability and statistics.

Additional Desired Skills: Numerical methods, Bayesian probability, Optimization, Parallel computing, Differential equations.

Transport of viscous fluids in porous material

Faculty Advisor: Arezoo Ardekani

Project Description: The main goal of this project is to characterize transport of viscous fluids through a porous matrix. Recently, simple and inexpensive methods for fabricating microfluidic devices in papers using a commercially available printer has attracted much attention. Fundamental understanding of transport in porous papers is necessary to optimize performance of these paper-based point-of-care diagnostic devices. A mesoscopic method called dissipative particle dynamics (DPD) will be used to capture the interaction of droplets with a porous paper with different surface properties (i.e., hydrophilicity and hydrophobicity). We will quantify the transport properties for different scenarios, by varying viscosity, surface properties, porosity and addition of macromolecules.

Suggested Majors: Mechanical Engineering, Chemical Engineering, Physics.

Required Skills: Fluid Dynamics or transport phenomena.

Additional Desired Skills: Programing, numerical simulations.

Deep learning based potential-energy discovery for large-scale molecular dynamics simulations

Faculty Advisor: Guang Lin

Project Description: The potential energy used in molecular dynamics plays crucial role in the accuracy of the results. In this project, we will employ the deep neural network to identify the optimum functional form of such potential energy. Deep artificial neural networks have been widely used in machine learning. This method is very general and applicable to different material systems and numerically accurate and fast to evaluate. We will employ this method to identify the potential energy related to semiconductors and energy-storage devices, such as Li-ion battery.

Suggested Majors: Industrial engineering, electric engineering, chemical engineering, mechanical engineering.

Required Skills: Programing skills in Python and Matlab.

Additional Desired Skills: Math skill in linear algebra, some basic skill in machine learning.

Efficient crystal structure prediction of drug molecules

Faculty Advisor: Lyudmila Slipchenko

Project Description: Accurate prediction of stable crystal structures of potential drug molecules is a taxing challenge in the pharmaceutical industry. Pharma companies have faced immense losses in the past due to crystal polymorphism – the process by which a bioactive drug spontaneously morphs into another less potent form. Our research group has been actively involved in the development of the Effective Fragment Potential (EFP) method that can be used in predicting the crystal structures and properties of drugs and other materials. Apart of the development of novel computational models and algorithms, we also work on packaging our methodology in an easy-to-use software called Simplexity. The current project will aim at publication of the new software tool at NanoHUB.

Suggested Majors: computer science, computer engineering, chemical engineering, chemistry, physics.

Required Skills: none.

Additional Desired Skills: knowledge of computer languages (Python, C/C++, Java, Fortran, MySQL) would be a strong asset.

Project 1: Understanding powder compaction with single particle measurements

Faculty Advisor: Marcial Gonzalez

Project Description:

Overall goal: The goal of this project is to develop new, and improve current, capabilities for modeling, simulation and prediction of microstructure formation and evolution during the compaction of powders.

Motivation: Compaction of powders is a manufacturing process used in many industries. It consists of the synthesis of loose powders into solid bodies. Many materials need to be made (or can only be made) in the form of small particles. The final products made of these materials, however, need to be of macroscopic size. The performance of these final products is directly related to their microstructural features, thus the fundamental understanding of the compaction process becomes of paramount importance. Nano-powders are pressed into solids to achieve unique thermo-electric and mechanical properties needed for electronic, energy and aerospace applications. Powder compaction is also used in the metallurgical, food, nuclear and pharmaceutical industry.

Description of the project:The specific goal of the project is three-fold: (i) explore the use of single particle measurements as a methodology for extracting mechanical properties relevant to the nanoHUB toolPowder Compaction, (ii) assess the efficacy of these measurements to predict powder compaction curves, (iii) fabricate powder compacts and validate these predictions.

Suggested Majors: Mechanical Engineering, Materials Engineering, Chemical Engineering, Computer Science.

Required Skills:

- Understanding some basics about materials mechanical properties

- Basic coding experience in MATLAB.

Additional Desired Skills: A strong desire to develop additional skills and knowledge.

Project 2: Microstructure evolution during compaction of powder blends

Faculty Advisor: Marcial Gonzalez

Project Description:

Overall goal: The goal of this project is to develop new, and improve current, capabilities for modeling, simulation and prediction of microstructure formation and evolution during the compaction of powders.

Motivation: Compaction of powders is a manufacturing process used in many industries. It consists of the synthesis of loose powder blends into solid bodies. Many materials need to be made (or can only be made) in the form of small particles. The final products made of these materials, however, need to be of macroscopic size. The performance of these final products is directly related to their microstructural features, thus the fundamental understanding of the compaction process becomes of paramount importance. Nano-powders are pressed into solids to achieve unique thermo-electric and mechanical properties needed for electronic, energy and aerospace applications. Powder compaction is also used in the metallurgical, food, nuclear and pharmaceutical industry.

Description of the project: The specific goals of the project are to expand the current capabilities of the nanoHUB tool Powder Compaction by: (i) modeling compacted products of different shapes and sizes, (ii) accounting for mixtures of powders with different particle size distributions.

Suggested Majors: Mechanical Engineering, Materials Engineering, Chemical Engineering, Computer Science.

Required Skills:

- Understanding some basics about materials mechanical properties

- Basic coding experience in MATLAB.

Additional Desired Skills: A strong desire to develop additional skills and knowledge.

Simulation and validation of self-assembly in nanocrystal inks

Faculty Advisor: Timothy Fisher

Project Description: Understanding the physics of manufacturing heterogenous materials via the popular processes of granular jamming, colloidal gelation and nanoparticle self-assembly is crucial to designing tailored materials deposited in inks for functional applications such as energy devices (thermoelectrics, photovoltaics), bio-sensing and electrocatalysis. At sub-micron length scales, the interparticle interactions are complex and dominated by conservative (van der Waals and electrostatic) and entropic (polymer-mediated or depletion dictated by particle shape) forces. This project seeks to develop a consolidated, web-based suite of computational tools (to be hosted on nanoHUB) to simulate the aforementioned processes. We employ optimization routines to explore the free energy hyperspace and predict stable microstructures along with detailed geometric (incl. visual) and mechanical characterization. The availability of such tools (for rapid prototyping these materials) through an open-source outlet will be of great benefit to researchers (experimental and computational) working in this field.

Expected Student Contributions: This project is primarily computational and will involve: a) object-oriented development (and extension) of existing prototype code for simulations, b) hosting the code on nanoHUB for a web-based interface, and c) exploring approaches for code parallelization.

Desired Qualifications: Strong programming skills. Knowledge of MATLAB, C/C++ is required. Prior experience with object-oriented programming is highly desired. Willingness to learn the principles of soft condensed matter physics.