High-Aspect-Ratio Micromachining of Titanium: Enabling New Functionality and Opportunity in Micromechanical Systems Through Greater Materials Selection

Category

Published on

Abstract

Traditionally, materials selection has been limited in high-aspect-ratio micromechanical applications, due primarily to the predominance of microfabrication processes and infrastructure dedicated to silicon. While silicon has proven to be an excellent material for many of these applications, no one material can meet the needs of all applications. This is especially evident in biomedical microdevice applications, where the intrinsic brittleness of silicon limits its utility, thus illustrating the need for development of viable alternatives. Titanium is particularly promising in this regard, due to its toughness, biocompatibility, and fatigue resistance. However, lack of sufficient fabrication capability has limited its use in micromechanical systems thus far.

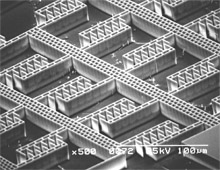

Scanning electron micrograph of a titanium-based MEMS device.

Recently, we reported the development of novel micromachining processes that now enable realization of this promise. These processes, based on plasma etching techniques derived from microelectronics manufacturing, provide for the first time, the capability for fabrication of complex, micrometer-scale, high-aspect-ratio structures in titanium. As such, these processes extend the state of the art in titanium micromachining and do so in a manner that is inherently scalable to low-cost/high-volume manufacturing. The focus of this talk will be to detail these processes, their capabilities, and their use in the fabrication of micromechanical devices for biomedical applications.

Bio

Prof. Rao received his bachelors in Material Science and Engineering from the University of Florida and his Ph.D. in Materials Engineering from the University of California, Santa Barbara (UCSB). Following graduation, he accepted a position as a post-doctoral researcher in the Mechanical Engineering Department at UCSB, where he was involved in the initial development of plasma-based micromachining of titanium. He joined the School of Mechanical Engineering at Purdue University as an Assistant Professor in January 2007. Prof. Rao’s current research interests lie in the continued development of titanium micromachining and its application towards biomedical microdevices, as well as the development of other novel microfabrication technologies for various applications. He has authored/co-authored over 20 journal articles and conference proceedings, and has presented lectures in fields ranging from ceramic composites for gas turbine applications to MicroElectroMechanical Systems (MEMS) for telecommunications and biomedical applications.

Prof. Rao received his bachelors in Material Science and Engineering from the University of Florida and his Ph.D. in Materials Engineering from the University of California, Santa Barbara (UCSB). Following graduation, he accepted a position as a post-doctoral researcher in the Mechanical Engineering Department at UCSB, where he was involved in the initial development of plasma-based micromachining of titanium. He joined the School of Mechanical Engineering at Purdue University as an Assistant Professor in January 2007. Prof. Rao’s current research interests lie in the continued development of titanium micromachining and its application towards biomedical microdevices, as well as the development of other novel microfabrication technologies for various applications. He has authored/co-authored over 20 journal articles and conference proceedings, and has presented lectures in fields ranging from ceramic composites for gas turbine applications to MicroElectroMechanical Systems (MEMS) for telecommunications and biomedical applications. Sponsored by

Cite this work

Researchers should cite this work as follows: