Understanding Variation and Statistical Process Control: Process Variation and Statistical Process Control (SPC)

Understanding Variation and Statistical Process Control: Process Variation and Statistical Process Control (SPC)

-

1. Understanding Variation and St…

0

00:00/00:00

1. Understanding Variation and St…

0

00:00/00:00 -

2. Outline

27.160493827160494

00:00/00:00

2. Outline

27.160493827160494

00:00/00:00 -

3. Corning Process to Manufacture…

82.082082082082081

00:00/00:00

3. Corning Process to Manufacture…

82.082082082082081

00:00/00:00 -

4. Measuring the Compression Laye…

319.31931931931933

00:00/00:00

4. Measuring the Compression Laye…

319.31931931931933

00:00/00:00 -

5. Responding to Variation in the…

406.57323990657324

00:00/00:00

5. Responding to Variation in the…

406.57323990657324

00:00/00:00 -

6. Responding to Variation in the…

585.45211878545217

00:00/00:00

6. Responding to Variation in the…

585.45211878545217

00:00/00:00 -

7. Limits to the Process vs Speci…

639.23923923923928

00:00/00:00

7. Limits to the Process vs Speci…

639.23923923923928

00:00/00:00 -

8. Limits to the Process vs Speci…

792.79279279279285

00:00/00:00

8. Limits to the Process vs Speci…

792.79279279279285

00:00/00:00 -

9. Histogram of the Glass Strain …

829.7630964297631

00:00/00:00

9. Histogram of the Glass Strain …

829.7630964297631

00:00/00:00 -

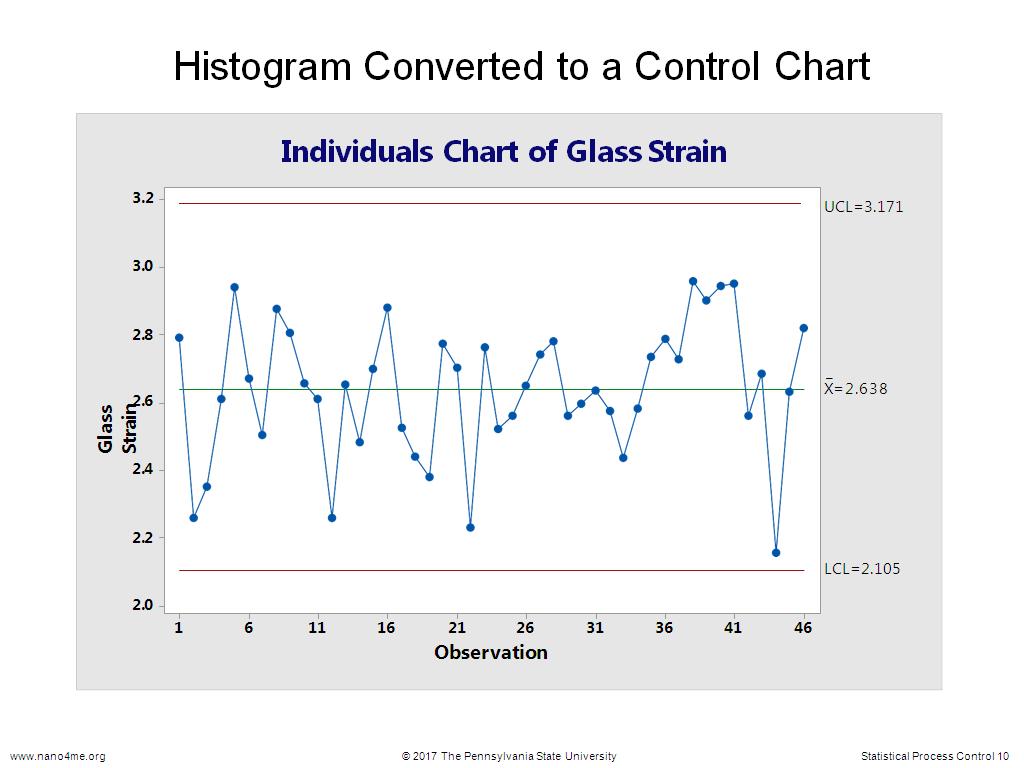

10. Histogram Converted to a Contr…

960.593927260594

00:00/00:00

10. Histogram Converted to a Contr…

960.593927260594

00:00/00:00 -

11. Characteristics of a Control C…

1050.4838171504839

00:00/00:00

11. Characteristics of a Control C…

1050.4838171504839

00:00/00:00 -

12. Sources of Variation – Time …

1154.421087754421

00:00/00:00

12. Sources of Variation – Time …

1154.421087754421

00:00/00:00 -

13. Sources of Variation – Commo…

1386.8535201868535

00:00/00:00

13. Sources of Variation – Commo…

1386.8535201868535

00:00/00:00 -

14. Identifying Special Cause Vari…

1556.1895228561896

00:00/00:00

14. Identifying Special Cause Vari…

1556.1895228561896

00:00/00:00 -

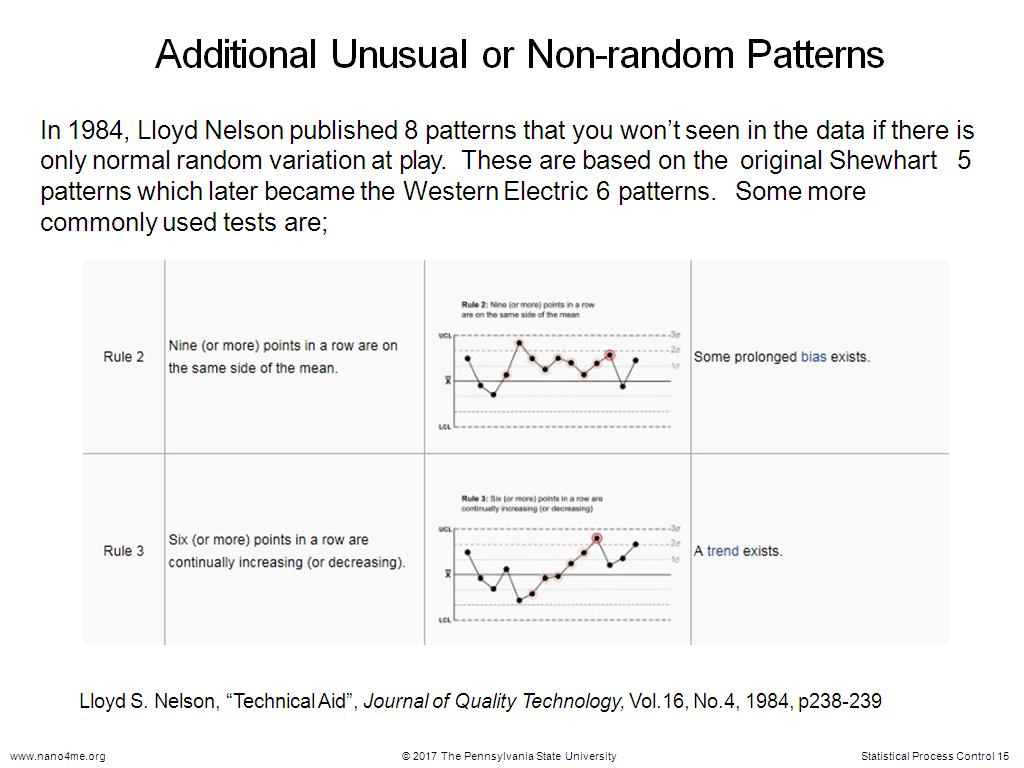

15. Additional Unusual or Non-rand…

1647.6810143476812

00:00/00:00

15. Additional Unusual or Non-rand…

1647.6810143476812

00:00/00:00 -

16. Additional Unusual or Non-rand…

1864.964964964965

00:00/00:00

16. Additional Unusual or Non-rand…

1864.964964964965

00:00/00:00 -

17. Determining Patterns from Spec…

1965.0984317650984

00:00/00:00

17. Determining Patterns from Spec…

1965.0984317650984

00:00/00:00 -

18. Eight Tests for Special Cause …

2144.4110777444112

00:00/00:00

18. Eight Tests for Special Cause …

2144.4110777444112

00:00/00:00 -

19. Identifying Special Cause Vari…

2330.4304304304305

00:00/00:00

19. Identifying Special Cause Vari…

2330.4304304304305

00:00/00:00 -

20. Identifying Special Cause Vari…

2352.9863196529864

00:00/00:00

20. Identifying Special Cause Vari…

2352.9863196529864

00:00/00:00 -

21. Dry Etch Process for Microproc…

2404.0040040040039

00:00/00:00

21. Dry Etch Process for Microproc…

2404.0040040040039

00:00/00:00 -

22. Value of Collecting Subgroup D…

2568.9356022689358

00:00/00:00

22. Value of Collecting Subgroup D…

2568.9356022689358

00:00/00:00 -

23. X-bar & R Chart of the Process

2714.9149149149152

00:00/00:00

23. X-bar & R Chart of the Process

2714.9149149149152

00:00/00:00 -

24. Identification of Out-of Contr…

2852.5525525525527

00:00/00:00

24. Identification of Out-of Contr…

2852.5525525525527

00:00/00:00 -

25. Advantages of the X-bar & R Ch…

2891.1911911911911

00:00/00:00

25. Advantages of the X-bar & R Ch…

2891.1911911911911

00:00/00:00 -

26. When to use the I- Chart

3105.7724391057727

00:00/00:00

26. When to use the I- Chart

3105.7724391057727

00:00/00:00 -

27. The Xbar and S Chart

3201.901901901902

00:00/00:00

27. The Xbar and S Chart

3201.901901901902

00:00/00:00 -

28. When to use the S Chart

3265.4654654654655

00:00/00:00

28. When to use the S Chart

3265.4654654654655

00:00/00:00 -

29. Conclusions

3388.4217550884218

00:00/00:00

29. Conclusions

3388.4217550884218

00:00/00:00 -

30. References

3506.3063063063064

00:00/00:00

30. References

3506.3063063063064

00:00/00:00