ME 290R Lecture 2.2: Lithography Performance Criteria - Technical (Yield Modeling)

ME 290R Lecture 2.2: Lithography Performance Criteria - Technical (Yield Modeling)

-

1. Lecture 2.2 Lithography Perfor…

0

00:00/00:00

1. Lecture 2.2 Lithography Perfor…

0

00:00/00:00 -

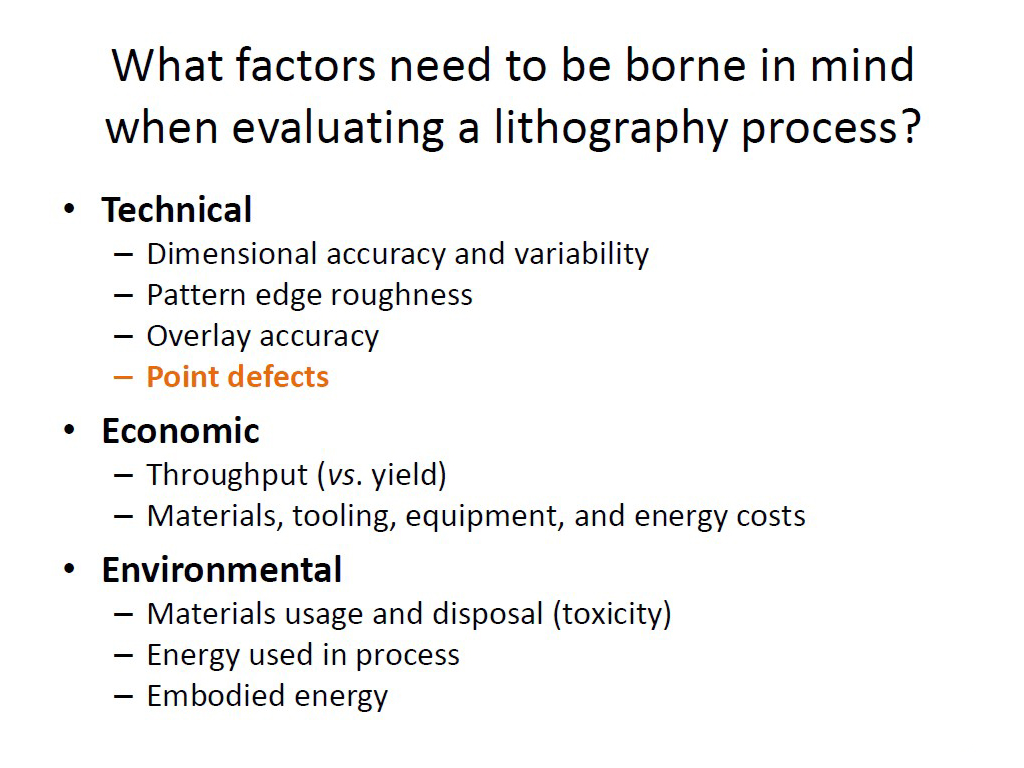

2. What factors need to be borne …

48.915582248915584

00:00/00:00

2. What factors need to be borne …

48.915582248915584

00:00/00:00 -

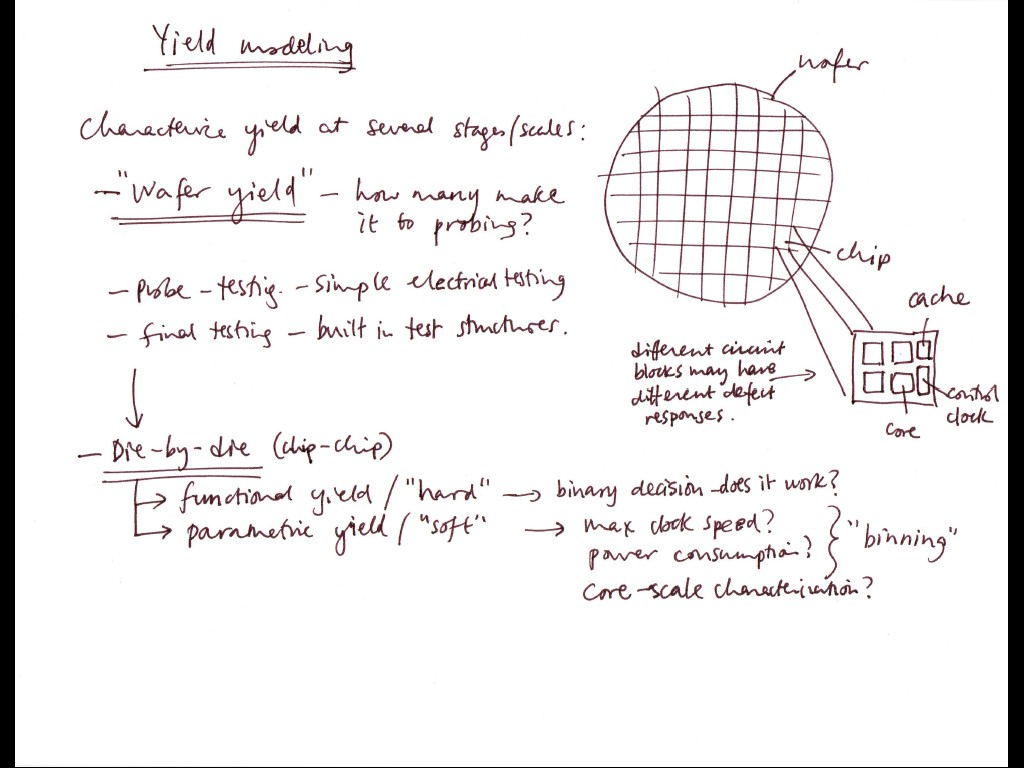

3. Yield Modeling

55.155155155155157

00:00/00:00

3. Yield Modeling

55.155155155155157

00:00/00:00 -

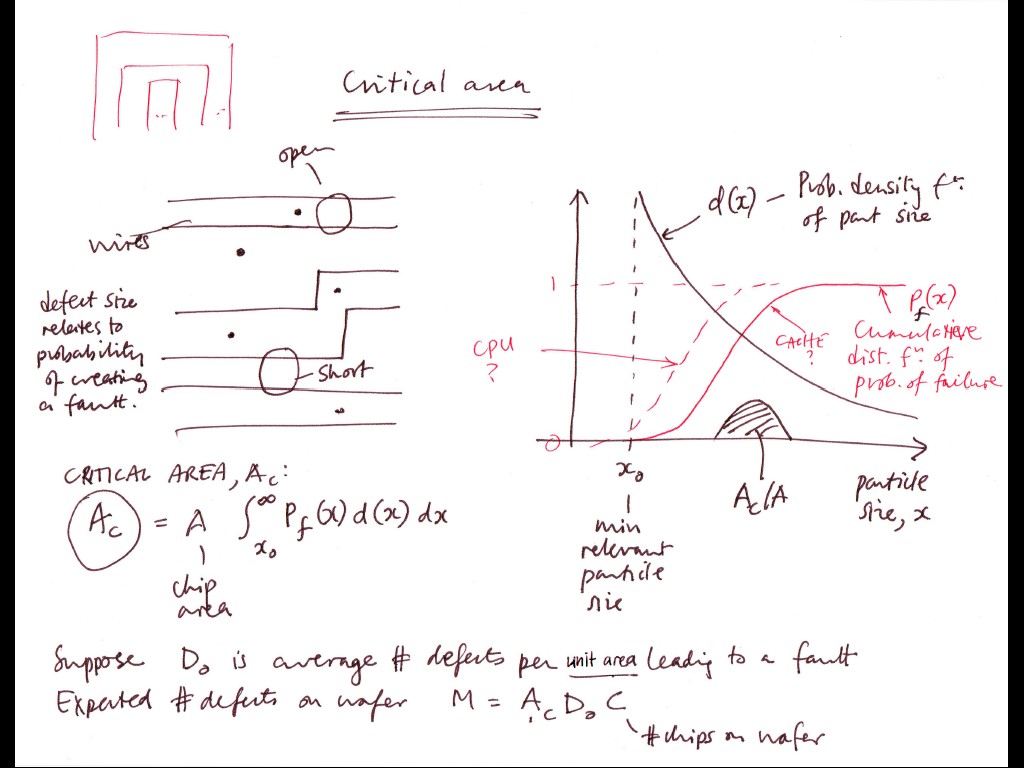

4. Critical area

687.2205538872206

00:00/00:00

4. Critical area

687.2205538872206

00:00/00:00 -

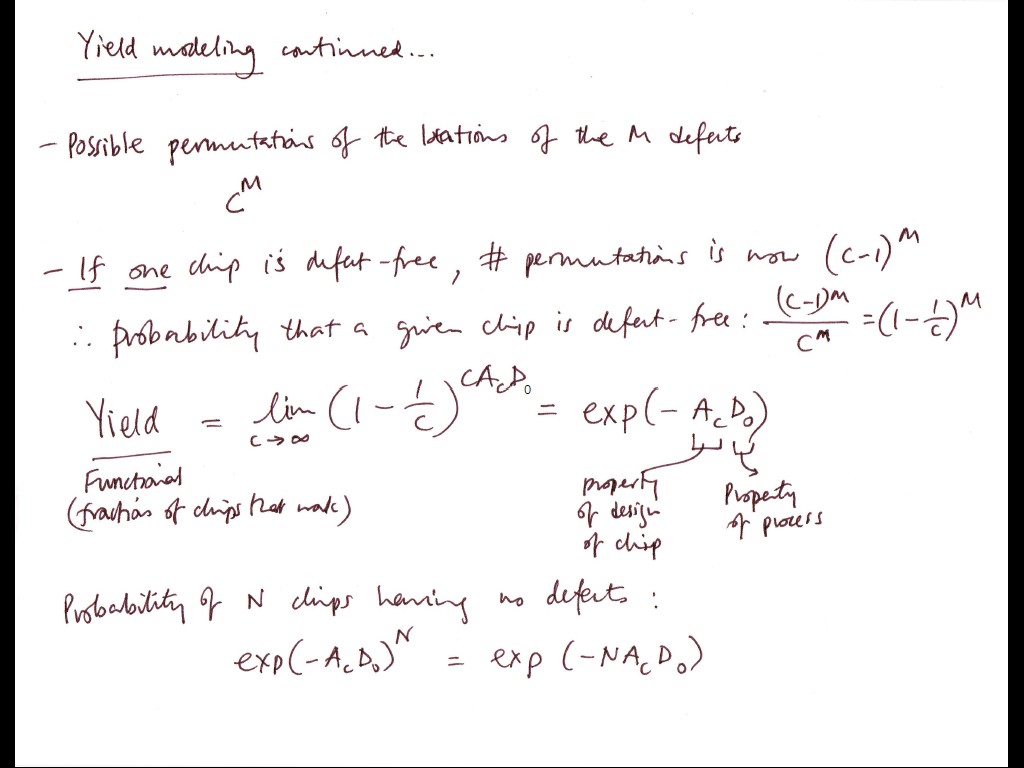

5. Yield modeling continued

1205.6723390056725

00:00/00:00

5. Yield modeling continued

1205.6723390056725

00:00/00:00 -

6. How can we characterize manufa…

1614.2809476142811

00:00/00:00

6. How can we characterize manufa…

1614.2809476142811

00:00/00:00 -

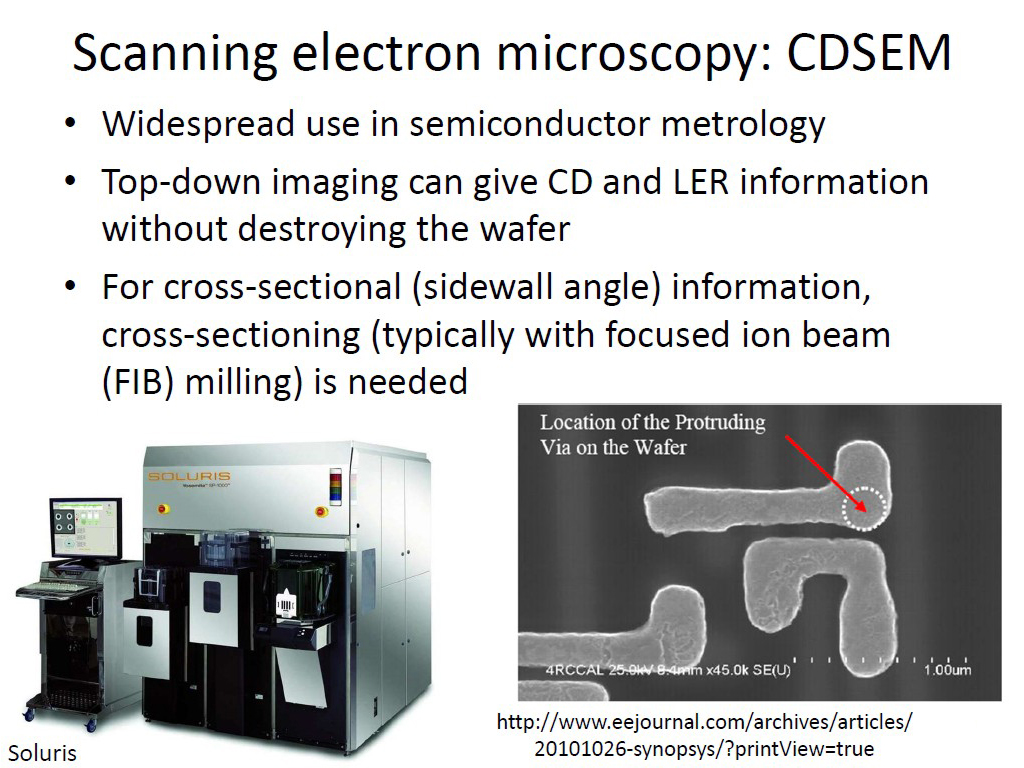

7. Scanning electron microscopy: …

1674.7080413747081

00:00/00:00

7. Scanning electron microscopy: …

1674.7080413747081

00:00/00:00 -

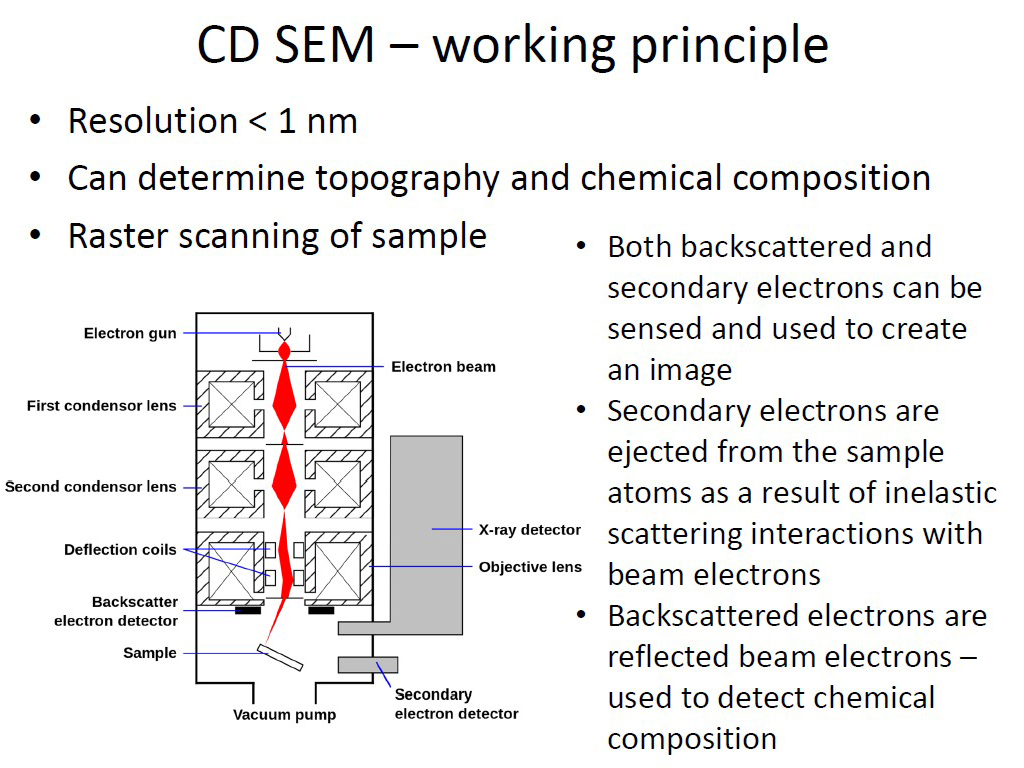

8. CD SEM - working principloe

1743.4100767434102

00:00/00:00

8. CD SEM - working principloe

1743.4100767434102

00:00/00:00 -

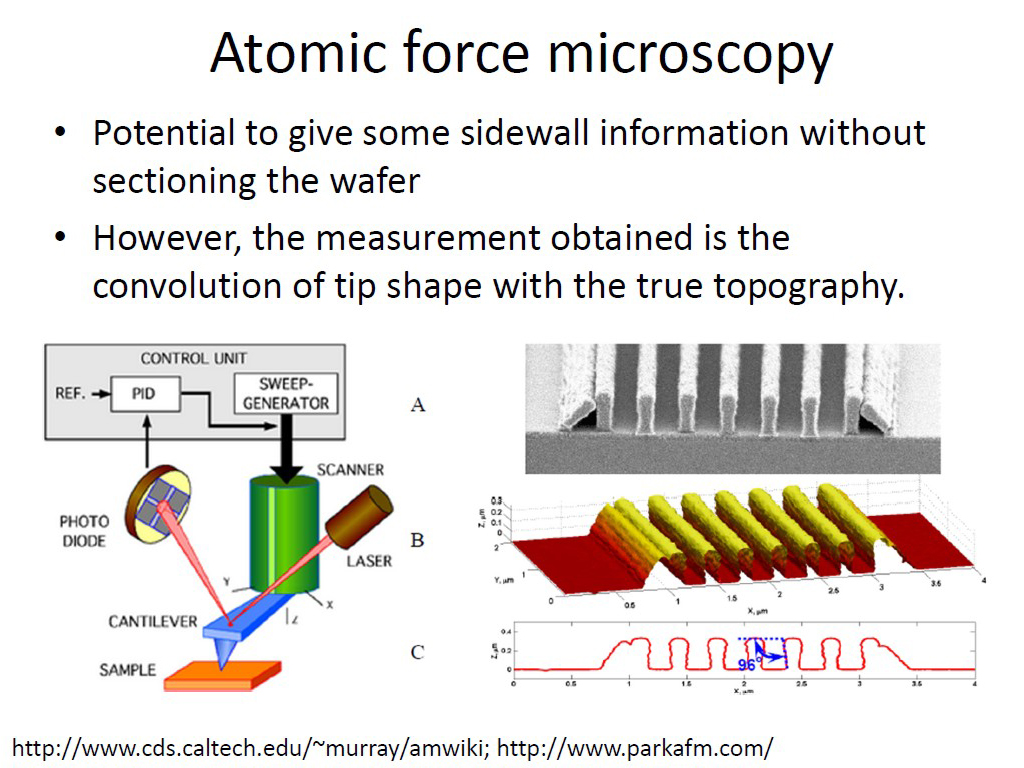

9. Atomic force microscopy

1752.218885552219

00:00/00:00

9. Atomic force microscopy

1752.218885552219

00:00/00:00 -

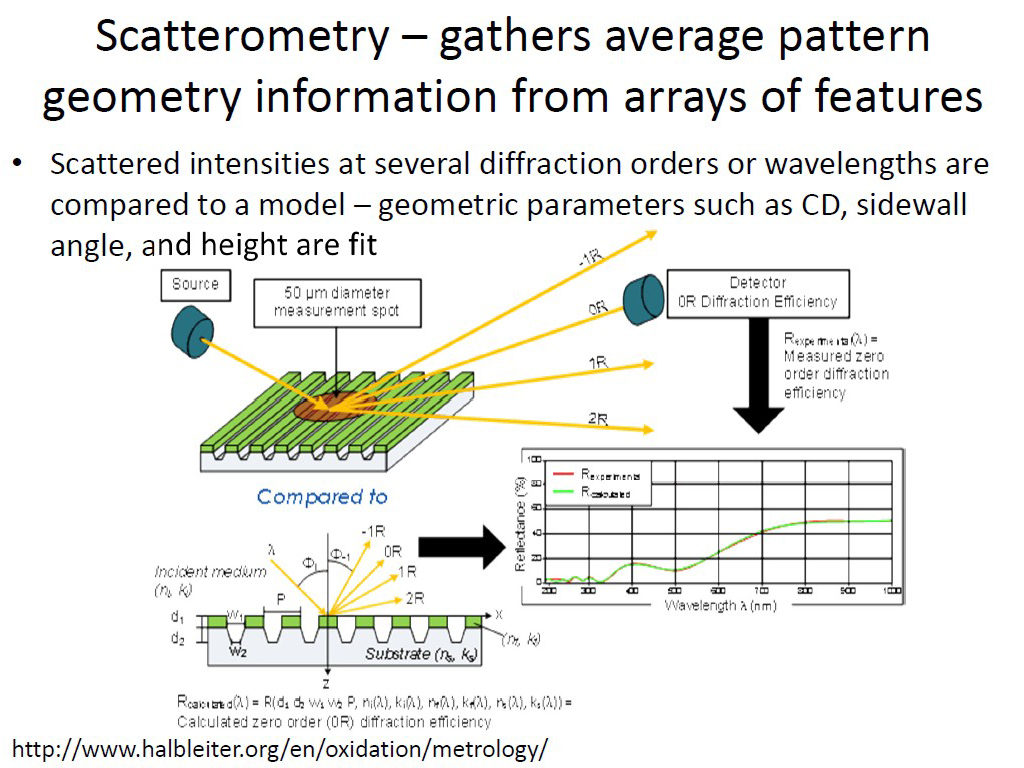

10. Scatterometry

1951.3513513513515

00:00/00:00

10. Scatterometry

1951.3513513513515

00:00/00:00 -

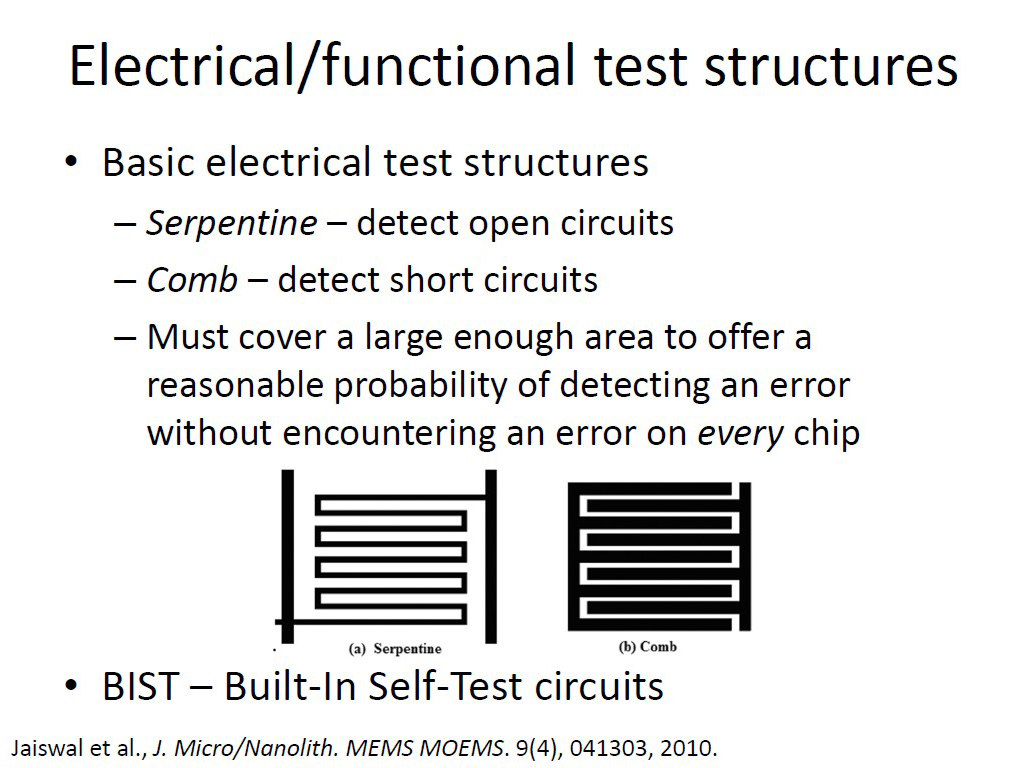

11. Electrical/functional test str…

2223.1564898231568

00:00/00:00

11. Electrical/functional test str…

2223.1564898231568

00:00/00:00